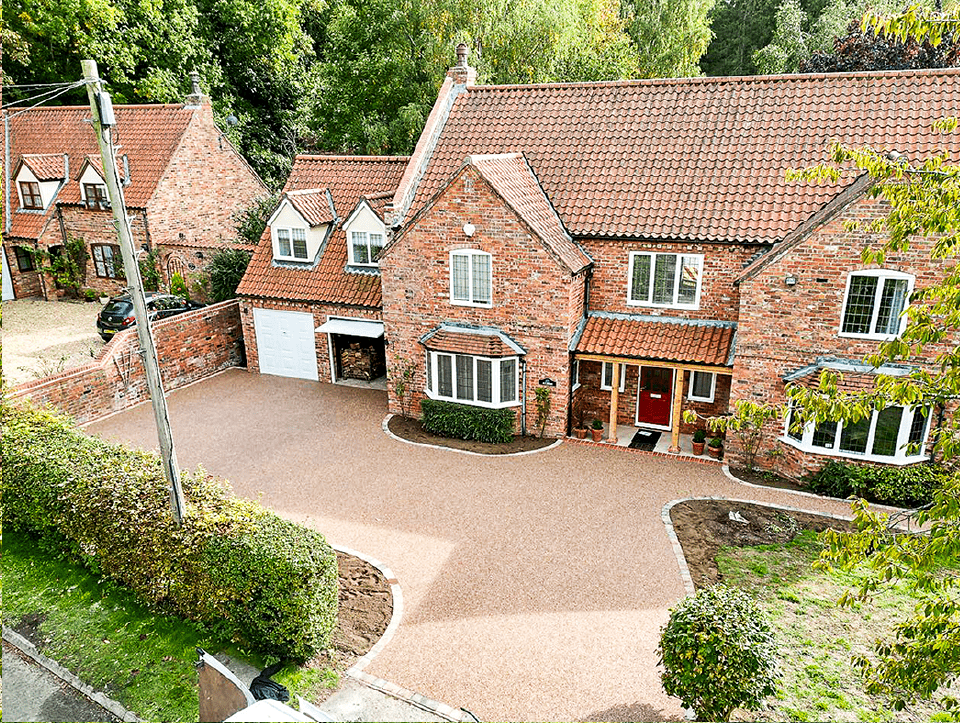

A well-kept driveway plays a vital role in creating kerb appeal for any property. With a wide range of materials available, each with its own benefits and drawbacks, UK homeowners and driveway installers face the challenge of choosing the right driveway finish to meet individual requirements and local conditions.

Concrete and asphalt both provide low-maintenance, durable solutions, but may not be particularly attractive from an aesthetic standpoint. Gravel and block-paving driveways can cost a small fortune to install and will require frequent care and attention to maintain their appearance.

With so many options available, it can be difficult to determine which material offers the best balance of in terms of installation and material cost, durability, maintenance, and aesthetic appeal. Two of the most popular choices today are resin driveways and block paving, both of which offer a range of benefits.

Looking at a resin bound surface vs block paving, which is the better choice for a driveway material and can provide the best investment over time?

Installing a resin driveway is quicker and cleaner

When a driveway is in constant use, one of the most significant advantages of resin bound driveways over block paving alternatives is the installation process itself. Resin driveways are comparatively easy to install when a suitable base for the resin materials is already in place, and can therefore be completed within a much shorter time window than block paving.

It's time consuming to install block paving driveways

Block paving is a more time-consuming and labour-intensive process. A solid base must first be compacted, then each block paving piece laid individually. With labour costs accounting for a significant share of the total driveway investment, they can be more costly to install than resin driveways.

Resin can be installed in half the time

Depending on the driveway area and prevailing weather conditions, a typical block paving driveway will take between five and seven days to complete. In contrast, a similarly sized resin bound driveway will take just two to three days. Factor in a curing time of at least 24 hours, and the resin option can represent real savings in labour costs. In addition, the driveway can be back in use sooner.

Lower maintenance demands

Providing a convenient solution combining aesthetic appeal, efficient draining of surface water and a low maintenance option, resin bound surface driveways are also low maintenance over the years, with simple brushing and very occasional jet washing in some instances to keep the surface in prime condition. For block paving, it may be necessary over time to replace jointing sand, prevent and remove any weeds and even apply a sealant to keep the blocks in original condition and retain a long lasting driveway.

Resin driveways are more durable

For homeowners, driveway durability is an important consideration. When installed correctly, both resin bound surface driveways and block paving offer long term durability. However, resin bound surfaces are formed using a balanced mix of resin and aggregate, which adds to their overall strength and durability.

Resistant to damage

They are exceptionally resistant to damage such as cracks, colour fading and staining from spills and other materials, and will withstand heavy loads over time without demonstrating visible signs of wear and tear. UV stability means they protect against UV degradation over time when exposed to direct sunlight.

In the UK climate, they have an added benefit: they are porous, so surface water drains away effectively. During cold or wet weather spells, a resin bound surface generally performs better than block paving. As with any driveway material, proper preparation and installation are essential.

Remedial work to block paving might be required

Block paving too offers an attractive and long-term solution. However, over time, the nature of the block paving materials can mean they become subject to cracking and movement shift. This may result in an uneven surface and affect the installation's overall visual effect, requiring remedial work. Weed growth between the block paving may also lead to subsequent damage, and requires extra maintenance.

Repairing resin driveways is also a consideration. Block paving is easier to repair than a resin bound surface where small sections become damaged. However, settling of the base over time can cause problems and lead to dips that collect water and increase the risk of damage.

Resin driveways are maintenance-free

Maintenance costs are also an important consideration. Resin driveways typically require minimal upkeep over time. They are quick and easy to clean with a brush, complemented by a light pressure wash a couple of times a year at most. They resist oil staining and weed growth, and they do not require the application of additional sealants and protective coatings to remain in prime condition for use.

In contrast, block paving requires regular cleaning and sealing to prevent stains and damage, which can be time-consuming and expensive over time. Block paving is also prone to weeds or moss growing in the joints between the blocks, which means frequent care and attention are required to keep a weed-free driveway and avoid a more weathered look which can detract from the aesthetic.

Multiple design options with resin driveways

Appearance is also key, and both resin bound and block paving driveways offer a wide range of designs, colours, patterns and options which will enhance the appeal of any property.

Intricate patterns are possible with resin

Importantly, resin driveways can be customised to match your home's style. They are installed in a single, seamless layer, without visible joints, and in a comprehensive selection of resin bound colours and patterns to choose from, creating intricate patterns, including bespoke shades and even recycled materials.

Options for the inclusion of additional elements such as decorative aggregates further increases the possibilities and colour palette, with edging strips and stones to finish off the design choice. Resin bound driveways are generally selected to create a sleek, smooth surface and contemporary look and finish.

Block paving driveways offer classic appearance

By contrast, block paving creates a more classic, traditional look using natural stone, which offers less colour flexibility. Many block paving designs are also more limited, relying on block paving patterns such as herringbone and basketweave to achieve the desired finish. However, the texture and natural material is considered by many to add visual appeal.

Resin bound driveways offer better long-term value

Both resin bound and block paved driveways provide long term durability and excellent aesthetics. However, the resin bound vs block paving option is proving increasingly popular for homeowners thanks to its sleek and elegant finish, low maintenance requirements, resistance to heavy loads and permeability in compliance with SuDS regulations. So which material provides better value over time?

The overall cost of a driveway will depend on the area size, material quality, and installation complexity. Gradients, geometric shapes, and ease of access will also play a part. Geographical location will also have cost implications cost, with transport taken into consideration and also the general north/south divide.

Resin bound has a higher initial investment

When laid correctly, resin bound driveways may incur a higher initial installation cost; however, this is quickly offset by much lower maintenance costs with a surface requiring very little upkeep, long-term durability and improved weather resistance. Resin driveway cost is typically £100-£110 per square metre, based upon the existing surface being a solid base such as concrete or tarmac not exhibiting any visual signs of cracking or damage.

Block paving may be more affordable at the initial stage, however when you factor in additional costs such as regular cleaning, the need for weed control, remedial work replacing individual blocks for patch repairs within the block paving and even additional protective sealants and coatings over time, the long-term value should be calculated with these considerations in mind.

Material costs

For resin bound materials, these will be dependent upon the quality of the resin and the aggregate selected. Choosing specialist materials will dd to the overall effect but also to the finished price.

For block paving, choosing concrete blocks over clay or natural stone will reduce the overall cost. Additional costs to factor in include bedding materials and jointing compounds.

Installation costs

Looking at resin vs block paving, installing a resin bound driveway requires more specialist skills and installation tools, which may increase the initial cost. However, this may be offset by speed of installation. More labour-intensive block paving will take longer but may incur lower labour costs.

Preparation

Both resin and block paving driveways require a suitable base for installation, and costs will increase for both options where no suitable base already exists.

Maintenance Costs

Resin bound driveways require little or not routine maintenance. Brushing and occasional light pressure washing keep them in perfect order and prime condition.

Block paving driveways require significantly more maintenance including regular cleaning, resanding joints, weed control and even the application of additional waterproof sealant or protective coating.

Resin driveways are more environmentally friendly

National standards for sustainable drainage systems (SuDS) were introduced in 2010 under the Flood and Water Management Act to improve flood management and reduce the risk of surface flooding. SuDS water management systems allow water to infiltrate slowly into the ground rather than creating runoff that enters traditional drainage systems, which can lead to flooding. Planning permission is not required for driveways that use permeable materials.

Resin bound is SuDS compliant

All resin bound driveway surfaces are by nature compliant with SuDS regulations, exhibiting a porous structure. Edgings can also be specified as water-permeable. This enables water to filter through the surface into the ground, which is particularly useful in urban areas prone to flooding. This makes them a particularly eco-friendly, SuDS-compliant option with no planning permission required.

This has the added advantage of reducing the risk of surface pooling, which can cause damage in wintry conditions. It also contributes to groundwater recharge, replenishing groundwater levels, and acts as a filter for urban pollutants. Their anti-slip, smooth surface also makes them safe underfoot, even in wet conditions.

Some but not all block paving is SuDS compliant

By contrast, not all block paving materials are SuDS compliant, although there are a some which do comply. Additional drainage systems may be required to achieve full compliance, and planning permission may be required for driveways over a certain size to reduce flood risk. In addition, block paving can become very slippery when wet.

Resin driveways: the smarter choice

Choosing the right material for your new driveway can be difficult, but for resin-bound systems vs block paving, resin offers the best balance of cost, durability, and aesthetic appeal in comparison with block paved alternatives.

Resin driveways offer a faster installation process, are highly durable, and require significantly less maintenance. They also offer a wider range of design options and are typically less expensive than block paving. In addition, they provide a totally permeable, environmentally friendly solution which is unlikely to require planning permission.

For answers to some of the most common questions about resin driveways, head to our FAQ page. Alternatively, contact our customer service team today for more information.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.