What happens when you take a 60m² driveway, one looming flight to America, and a resin installer determined to push his limits?

You get one of the most impressive and exhausting challenges Resin Mill has ever seen. Welcome to the story of the 24-Hour Driveway Challenge featuring Mark Marshall & Matt from resindrivewaysystems.co.uk.

Watch the video or read the post below.

The Mission Begins

Set in a quiet Birmingham suburb, this project began like many others… a tired old concrete driveway in desperate need of transformation. But with a tight schedule and only 24 hours on the clock, this was no ordinary resin driveway installation.

Mark Marshall, joined by Resin Mill approved contractors Matt and Taff, took on the challenge headfirst. The goal? Rip out, rebuild, and resurface the entire drive in just one day, all before Mark caught a flight to America. That’s right: no wiggle room, no second chances.

“The deadline wasn’t just about pushing ourselves - it was about honouring a commitment and proving what’s possible with the right prep and the right team.”

Hour 0–8: Rip-Out, Rebuild, Recharge (Sort Of)

The first eight hours were all-out war.

Armed with grinders, breakers, and a military-style plan, the team ripped out the old concrete, set new borders, and laid fresh permeable concrete. The goal? To be resin-ready by nightfall.

“Everything was planned before we even knocked on the customer’s door. That prep is what made this possible.”

It wasn’t without hiccups. A last-minute shortage of stone forced the crew to adjust and use more permeable concrete than expected. A costly pivot, but a necessary one to stay on track.

Hour 9–16: Resin, Red Brick, and Red Bull

With the base down and cured, it was time for the crown jewel, the resin bound top layer.

To complement the deep red tones of the home, Mark chose a best seller blend from Resin Mill’s Resin Bound Pro range called Dorset Cove. The finish? A rich, characterful surface that elevated the property’s kerb appeal tenfold.

Armed with Resin Mill's high-performance resin, a power float, and enough coffee to keep an army awake, the team pushed through the fatigue.

“It was full throttle all the way through - mixing, laying, finishing. The power float made a huge difference to keep us moving at pace.”

By the time the final trowel hit the surface, the team was running on fumes, but they’d done it.

The Big Reveal

The Big Reveal

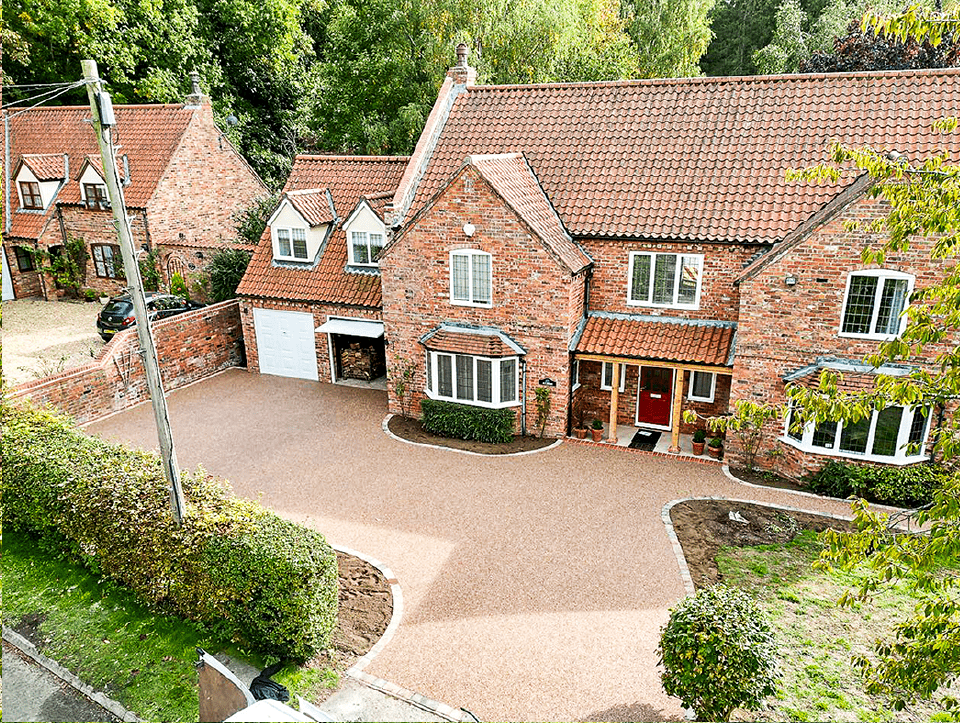

When the homeowner opened the door, she was speechless.

Her dull concrete driveway was now a stunning, durable, SuDs-compliant surface. A space she and her son could be proud of for 20+ years to come.

“She was blown away. That reaction made every hour, every ache and every gulp of coffee worth it.”

Mark’s Verdict

After only 7 months in the resin industry, Mark Marshall has already raised the bar. This wasn’t just about speed - it was about delivering excellence under pressure.

“I think it’s the best resin job I’ve ever done. I’m proud of what we achieved. And yes - I’d 100% do it again. In fact, next time I want to do it in one working day.”

The Resin Mill Difference

Why Resin Mill? According to Mark, it’s not just the premium products - it’s the people.

“The customer service, the support, the community - Resin Mill feels like a family. You’re not just buying materials. You’re building a relationship.”

Want to see more of Mark’s or Matt's incredible transformations?

Follow Mark on Facebook, Instagram, TikTok and YouTube - Just search Mark Marshall or Lawn Stripes & Hedges.

Contact Matt via his website for any resin bound driveways: resindrivewaysystems.co.uk

Watch this space - because this definitely won’t be his last challenge!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.