Resin Bonded & Resin Bound Edging Profiles

Believe it or not edging profiles are key when laying resin bound surfacing and here’s 3 reasons why. Edging profiles:

1) CONTAIN THE RESIN GRAVEL AND ACT AS A WORKING EDGE

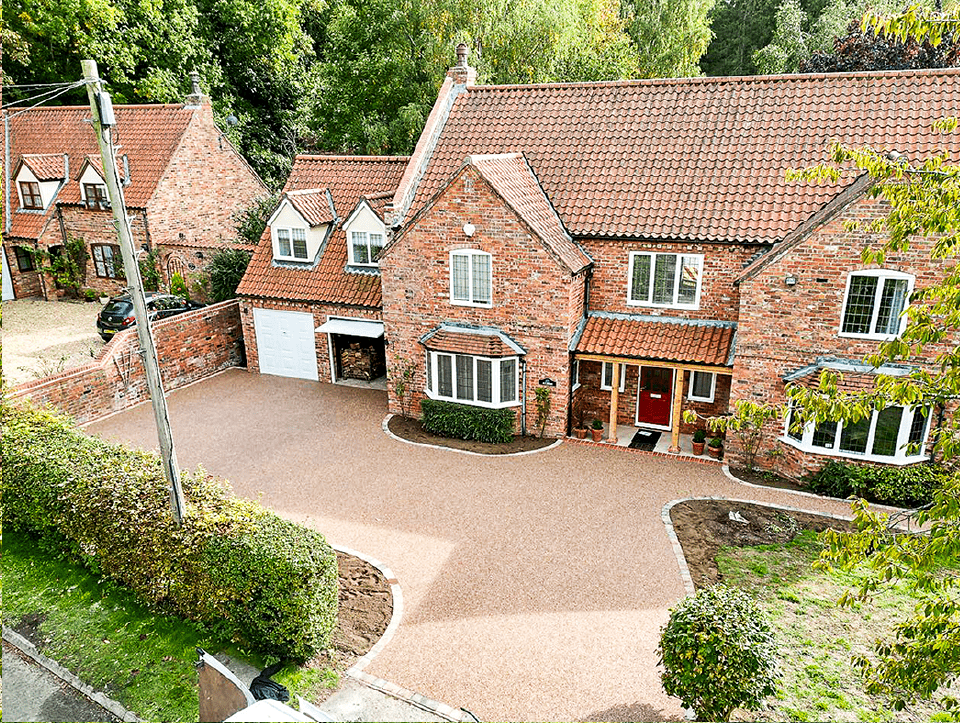

Because the surface courses of resin bound are quite thick, (usually between 15-18mm), a form of holding restraint is necessary to keep the bound gravel in the designated place. If there is not a border currently in place, create one. Traditionally in resin bound surfacing, edging has been in the format of bricks, pin kerb or walls, however straight or square edge aluminium profiles provide linear definition and protect the edges. Aluminium beading is often used in the permeable paving industry for cosmetic intentions, to offer a clean, professional finish. They give the contractor who is trowelling the resin bound aggregate, borders which to work toward, adding to the ease of the installation.

Use edging profiles when laying large surface areas. They introduce a break in the system (as the setting times won’t be long enough), so that there are no mechanical joints in the resin gravel.

2) ACT AS MOVEMENT JOINTS

If there is any movement in the sub-base, it will cause reflective cracking, as the sub-base underneath expands and contracts at different rates. To prevent reflective cracking the installation of movement joints is essential. They are installed for protection against the possible natural stresses that cause cracking and disfiguration in resin bound paving. It safely absorbs heat-induced expansion, essential for larger resin drive projects.

Poor workmanship in the anchoring of the profile-fixing flange can cause the movement joint to break out of the profile, because the infill material is too solid. We partner with Dural, as they specialise in movement joints and have the highest quality joints on the market. The angle of the profile and the choice of material can allow edge protection in areas of strong stress. British standards state that there must be a minimum absorption capacity of 20% of the infill width. Dural’s infill exceeds 20% absorption capacity, with a minimum of 30% in both compression and extension.

We can supply anything from Dural, our best sellers are the Durosol Straight Edge Profiles, Durosol Flexible Profiles and Movement Joint Profiles. Dural movement joints have an epoxy infill, offering a highly resilient solution with a predictable compressive performance.

3) FACILITATE DIFFERENT DESIGNS

The possibilities are endless when it comes to designing edging profiles for resin drives. Edging profiles can be customised at little to no extra cost. The epoxy material can be easily changed to give either a contrast or a colour match to the resin gravel; we have a full RAL colour chart to choose from. Selecting a different choice of metal can also customise each joint and profile. The dimensions and depths of the resin profiles can be easily changed to suit different project requirements. Some clients are adverse to movement joints. They think they spoil the visual impact of the resin bound however they are essential and an aluminium edge gives a neat and distinctive finish to surfaces of different materials.

We can supply Durosol Flexible Profiles, allowing the forming curves and designs on site, providing huge design capabilities. This allows flexibility for company logos, emblems, numbers and graphics to be incorporated in to permeable paving. The aluminium edging can be specially created to form stencils to bring resin bound and resin bonded projects to life. Profiles can be as bespoke or as standardised as possible. At The Resin Mill however, we are on hand to advise and assist from both a design and technical standpoint.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.