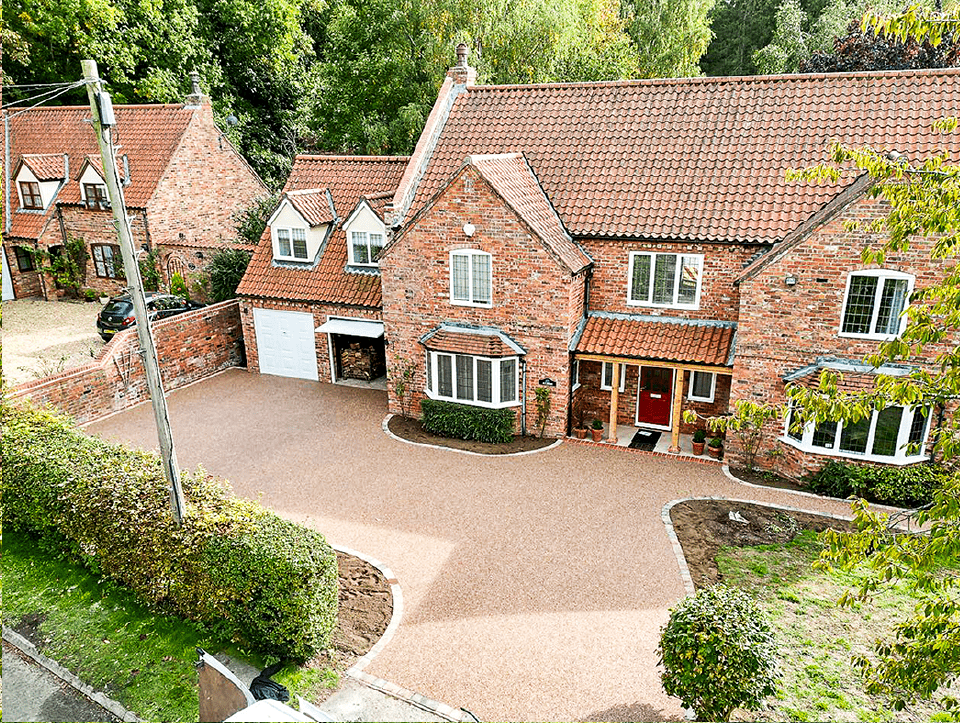

Much of the beauty of a resin driveway comes from the smooth and seamless surface it provides, making it suitable for both vehicles and people alike. That's why resin-bound surfaces are ideal for use as driveways or footpaths. However, as much as we talk about the finished result, it's often easy to forget about what's going on underneath.

Every resin driveway needs a base to be laid on top of, and as is so often the case with many home improvements, the finished result will only ever be as good as the preparation work beneath. A poor base can lead to cracking and potentially even the resin breaking up. But a good base will mean your resin driveway looks fantastic and performs faultlessly for many years, requiring virtually no maintenance other than the occasional jet wash.

What should you look out for before installation?

A reputable firm will undertake an assessment before installation of a resin-bound driveway, but homeowners can also look out for the following;

- Cracks or crumbling are signs that your existing tarmac or concrete base is not of high enough quality to support the installation.

- Surfaces that have fewer joints and are predominantly large slab areas, such as tarmac or concrete, provide the best finish.

- Nearby tree roots could create problems if their roots lift and disturb the paving.

- It is important that the moisture levels on the surface meet an acceptable level as recommended by the resin manufacturer.

Best base for resin driveways

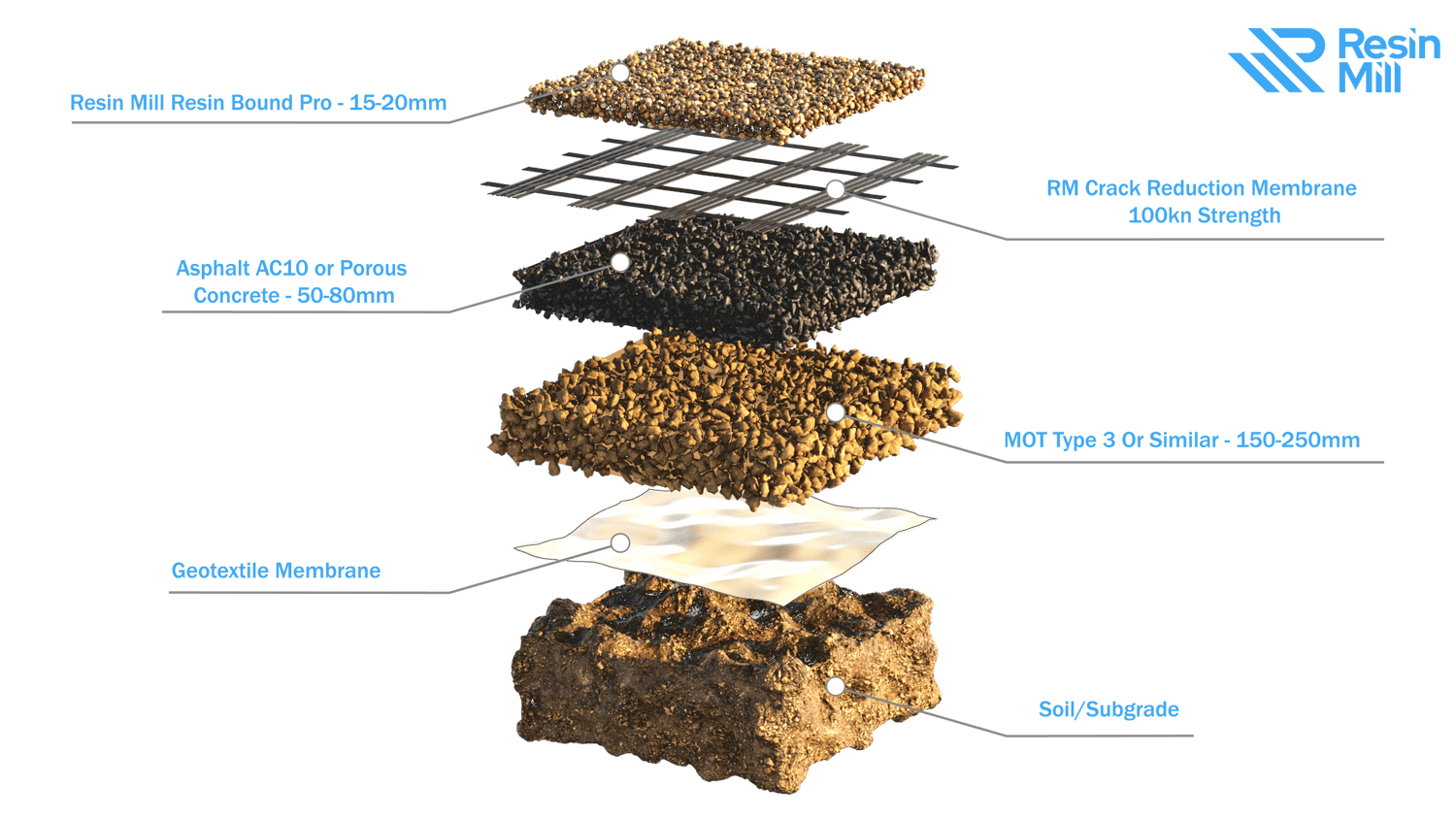

When it comes to bases for resin driveways, there are only a few realistic options: porous concrete, tarmac/asphalt or a grid system.

1. Tarmac base

Assuming it's laid on a suitable sub-base such as MOT type 3 and it's of good depth, resin driveways can be installed on top of the tarmac or asphalt, which will be a strong and stable sub-base enough to support the required weight.

If using tarmac as a sub-base, it should be left to set for a minimum of 2 weeks to let the oils deplete.

2. Porous concrete surfaces

If it's a new base, you'll need to allow seven days for the concrete to cure. Existing concrete must be thoroughly cleaned and primed with a polymer primer prior to the installation of the permeable paving.

If a primer is not laid, the two surfaces will fail to adhere, and your resin drive materials will be wasted. The only way to rectify the surface will be to restart the project with a new batch of resin bound materials.

In addition to the primer glueing the two surfaces together, it also helps prevent delamination between the surface and the concrete. The primer also creates a barrier between the two surfaces, which prevents the concrete from absorbing the resin out of the stone in the mixture. This is especially important for fresh concrete.

If the concrete has been newly set (on a sub-base of ideally MOT type 1), there must be a minimum of seven days before the initiation of the resin-bound. Sometimes it can take up to a month to cure. Again, the surface must be primed with a polymer-based primer before the porous pavement is installed.

3. Grid systems

Grid systems can also be used to support resin-bound aggregates. However, double the quantity of resin-bound supplies is needed, and so it can be costly.

Resin driveway bases to avoid

Block and brick paving

Unlike concrete and tarmac, block and brick paving isn't suitable because it doesn't provide the same solid base, and therefore isn't as safe a foundation for a resin driveway. The uneven nature of brick paving driveways means that if you did lay a resin driveway over the top, it is highly likely to start showing cracking almost immediately.

Paving flags

Paving slabs have a similar issue where too much movement can cause cracking. As the resin-bound surface is a dressing, usually installed at 18mm thickness for a driveway, it is essential that the substrate is as solid as possible and offers no movement.

Soil and grass should also be avoided as bases for resin-bound systems.

SUDS-compliant bases for resin driveways

One of the many advantages of a resin-bound driveway is the fact that it is porous and allows water to freely drain through the surface itself and remain fully compliant with current SUDS (Sustainable Urban Drainage System) regulations.

When installed correctly, our resin-bound driveways can drain as much as 850 litres of water per square meter per minute, thanks to the permeable nature of the material. However, that only works if the base beneath the resin surface can also handle the water drainage.

To achieve SUDS compliance, the base needs to be able to process the water, too. This can be done using a specialist blend of porous concrete or open grade, laid over Type 3 MOT aggregate that allows water to drain through and into the ground beneath.

Resin-bound vs Resin-bonded

While resin-bound surfaces are SUDS compliant, resin-bonded surfaces are not. This is because the resin is applied directly to the base layer and forms an impermeable barrier between the finished surface and the base layer. Any base layer that isn't SUDS-compliant will mean the whole installation is non-compliant.

Achieving SUDS compliance is important, as it means you can install a driveway of any size without the need for planning permission. If a resin driveway is not SUDS compliant, planning permission may be required for new driveways larger than 5m².

What can I lay my resin-bound gravel near?

Resin bound gravel can be installed against house walls, block edging, key curbs, pin curbs, fences, and aluminium beading.

Will my resin-bound ever crack?

The Resin Mill’s resin-bound is a flexible polyurethane system. The only reason it would crack is if there were reflective cracking in the sub-base. You can, however, combat reflective cracking. You can do this by enlarging the crack in the cement and filling it with resin-based crack filler. This will halt reflective cracking in the resin paving.

How can I be sure to get the highest standard resin driveway?

The resin overlay is only as good as the base underneath it. As the UK’s only resin-bound affiliate partner of HICS, we promote only the best base work and resin-bound installations.

For resin driveway help and advice, contact The Resin Mill

If you’re looking to install a resin driveway over an existing concrete, Tarmac, Bitmac or asphalt driveway and want to enjoy a smoother, more attractive surface, or you want to replace a maintenance-heavy block paving driveway in favour of a lower maintenance resin surface, get in touch with our experts today.

The Resin Mill is well-equipped to provide you with everything you need to know about installing the perfect resin driveway, including our fantastic resin training

You’ll find the answers to most of the commonly asked questions on our FAQs page, but to find out more, give us a call on 01484 213437 or get in touch with us via email or by completing our online form.

FAQs

What is the best type of base for a resin bound surface?

The best base for a resin bound installation is usually permeable tarmac (open-graded asphalt) or concrete, as both provide a stable, long-lasting foundation that supports the resin bound system and prevents cracking or movement. Permeable tarmac is preferred because it works seamlessly with the SuDS-compliant, free-draining nature of resin bound gravel.

Can resin bound gravel be laid over an existing surface?

Yes, resin bound gravel can be installed over existing tarmac or concrete as long as the surface is sound, level, and free from major cracks or structural weaknesses. Any damaged areas must be repaired before installation, and installers may need to apply a primer to ensure proper adhesion and a consistent final finish.

Do I need a permeable base for my resin bound driveway?

A permeable base is strongly recommended, especially if you want your driveway to be fully SuDS-compliant. When resin bound gravel is paired with a permeable base, rainwater drains naturally through the system, reducing the need for additional drainage and helping to prevent puddling or surface water runoff.

How deep should the base be for a resin bound system?

For most driveways, the base should typically be installed at at least 100–150mm, depending on the ground conditions and expected load. This ensures the surface remains stable under vehicle weight and prevents issues such as sinking, cracking or movement over time.

Can I use compacted stone or type 1 as a base for resin bound gravel?

While compacted stone can be used for some footpaths or decorative areas, it is not suitable for resin bound driveways because the surface is not stable enough and can shift under load. For best results and long-term performance, resin bound should always be installed onto a durable open open-textured tarmac at 70mm or a concrete base.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.