What Is Resin Bound Paving?

Resin bound paving is a blend of 100% naturally formed kiln-dried aggregates mixed thoroughly with polyurethane resin. Throughout the process each particle of aggregate is completely covered in the resin to form an architecturally solid, porous surface.

Why Are Resin Bound Surfaces Becoming So Popular?

Due to the upsurge of flooding in the UK and need for flooding prevention, the resin bound aggregate market has become ever so more desirable. Cost has also been a barrier until recently but the market has matured with companies now benefitting from economies of scale. Unlike tarmac, resin bound doesn’t break down in the heat and is a more durable solution.

The Resin Mill are heavily involved in research and development and are from our work in the laboratory we are ahead in advancements in resin bound systems.

Benefits Of Resin Bound Paving?

Versatility

Resin bound aggregates can be used for almost any project, regardless of scope or budget. Applications include but are not limited to: permeable paving, resin drives, resin patios, resin car parks, resin cycle paths, resin bus lanes, heritage sites, estate roads, schools, tree pits, swimming pool surrounds and garden and landscape designs, to name a few. Using conflicting resin stones you can inlay logos, emblems, slogans, numbers and wording.

Eco Benefits

Resin bound surfacing applied to an appropriately designed porous base and sub-base will facilitate design of a SuDS (Sustainable urban Drainage System) compliant permeable paving construction, reducing flood risk and allowing rainwater to flow in to natural watercourses. In turn it reduces water running off the surface, therefore reducing flooding and qualifies as SuDS permeable paving. There is no need to tear up the original sub-base, further adding to the eco benefits.

FACT: In Being SuDS Compliant, Planning Permission Is Not Required

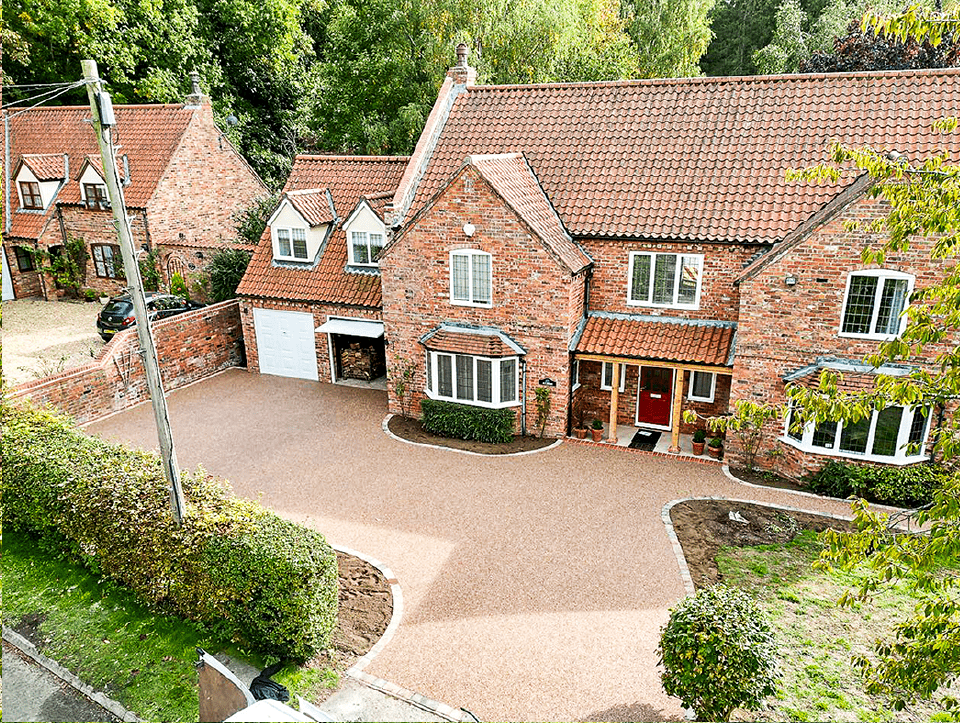

Cosmetically Pleasing

Resin bound gravel is extremely decorative as you can play with different colours and textures; yet generate an attractive seamless surface. Gravel resin allows design flexibility. Different shapes and patterns can be created which can incorporate company logos, emblems and slogans. A pebble look can be achieved and the aggregates won’t migrate due to the encapsulated aggregates. This enables a fluid feel that is also foot friendly.

Longevity and Resistant

Resin Mill resin bound supplies, when installed correctly can last for 20 years. Provided the correct resin is chosen, the colour won’t fade in the sun and the resin bound surfacing will not soften either.

Quick Installation and Limited Maintenance

Installation of resin bound gravel is a quick and easy process and smaller projects can be completed in the day. Resin bound suppresses weed growth but a yearly power wash will keep it looking as good as new.

Click here to find out more about the cost of resin driveways.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.