Discover Resin Bound

What Is Resin Bound Surfacing?

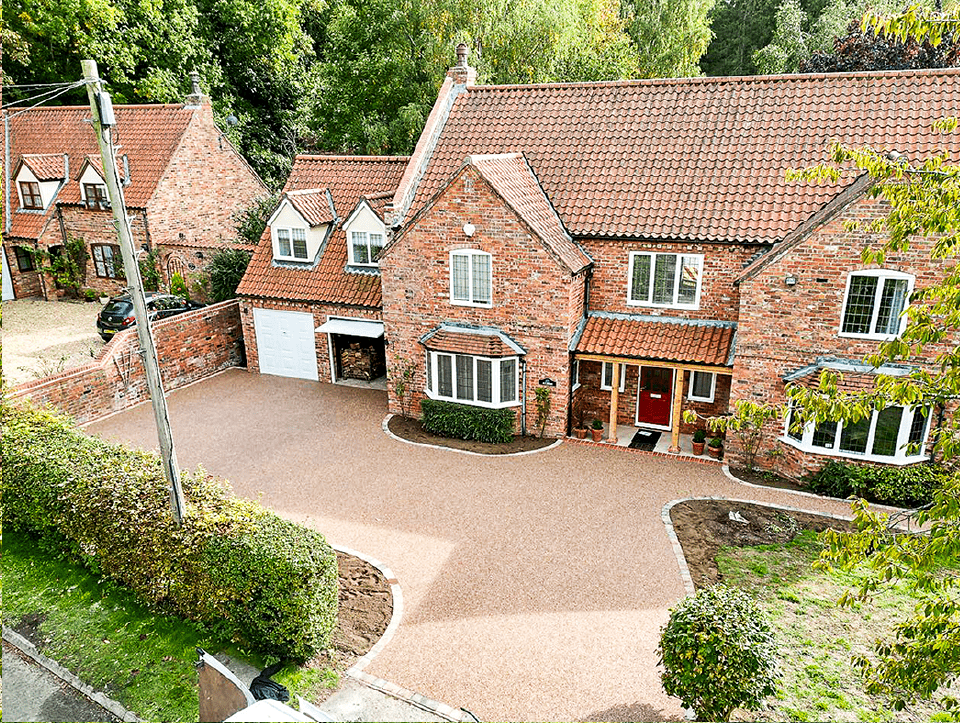

Resin bound surfacing is a modern, durable, and aesthetically pleasing paving solution created by mixing natural 1-5mm aggregates with a clear two part polyurethane resin. This resin and stone mixture is then applied to a prepared base and hand-trowelled to form a smooth, seamless finish. It’s a popular choice for driveways, pathways, patios, and public spaces thanks to its attractive appearance and long-lasting performance.

Unlike loose gravel or traditional tarmac, resin bound driveways are fully bound, meaning every stone is coated in resin before being laid. This ensures a solid, stable surface that is both slip-resistant and highly durable. Purchasing your resin bound materials from Resin Mill over other suppliers ensures you have access to our advanced products, which guarantee the highest quality surfaces to ensure years of lasting beauty.

ADVANTAGES OF RESIN BOUND

- WATER PERMEABLE Resin bound is SUDs compliant and allows water to drain through the surface preventing puddles from forming and flooding. This also means no planning permission is required.

- LOW MAINTENANCE Resin bound is weed resistant and requires jet washing occasionally to remove dirt .

- ECO FRIENDLY Our materials have been carefully sourced from quarries across Europe.

- SEAMLESS FINISH Get a smooth and seamless finish with our resilient and durable resin bound surfaces.

- BOOSTS HOME VALUE Resin bound surfacing adds unique beauty and value to your home.

- A TOUCH OF COLOUR With 26 colours available, you’ll be able to create a unique surface just for you.

- SLIP RESISTANT A safer space all year round.

- ADAPTIVE Works in any area or shape.

What Type Of Resin Do We Sell?

Resin Bound UVR Pro is a two-part polyurethane resin kit that is UV stable. This means that the resin surface won’t yellow, change colour or fade over time. Resistant, tough polymers make our resin one of the strongest, yet most flexible on the market, ensuring a stable, durable and resistant resin surface. You can rest assured your new surface will last the test of time, when using our resin bound materials and following the correct installation guidelines.

ENSURE THIS ALWAYS!

Not all resin products make equally strong surfaces. Always choose resin with a 50:50 (or 1:1) ratio, which makes stronger bonds and creates a more hard-wearing, longer-lasting driveway, path or patio.

What Type Of Aggregates Do We Sell?

At Resin Mill, we believe that your home deserves products that are built to last - both in appearance and performance. That’s why we created Resin Rox: a premium range of washed, dried, and carefully graded aggregates designed specifically for resin bound surfaces.

Unlike general aggregates on the market, Resin Rox is engineered to work perfectly with resin. Every stone is selected not just for its colour and beauty, but for its shape, strength, and compatibility with resin technology. The result? A longer-lasting, more durable surface that’s UV-stable, crack-resistant, and low-maintenance.

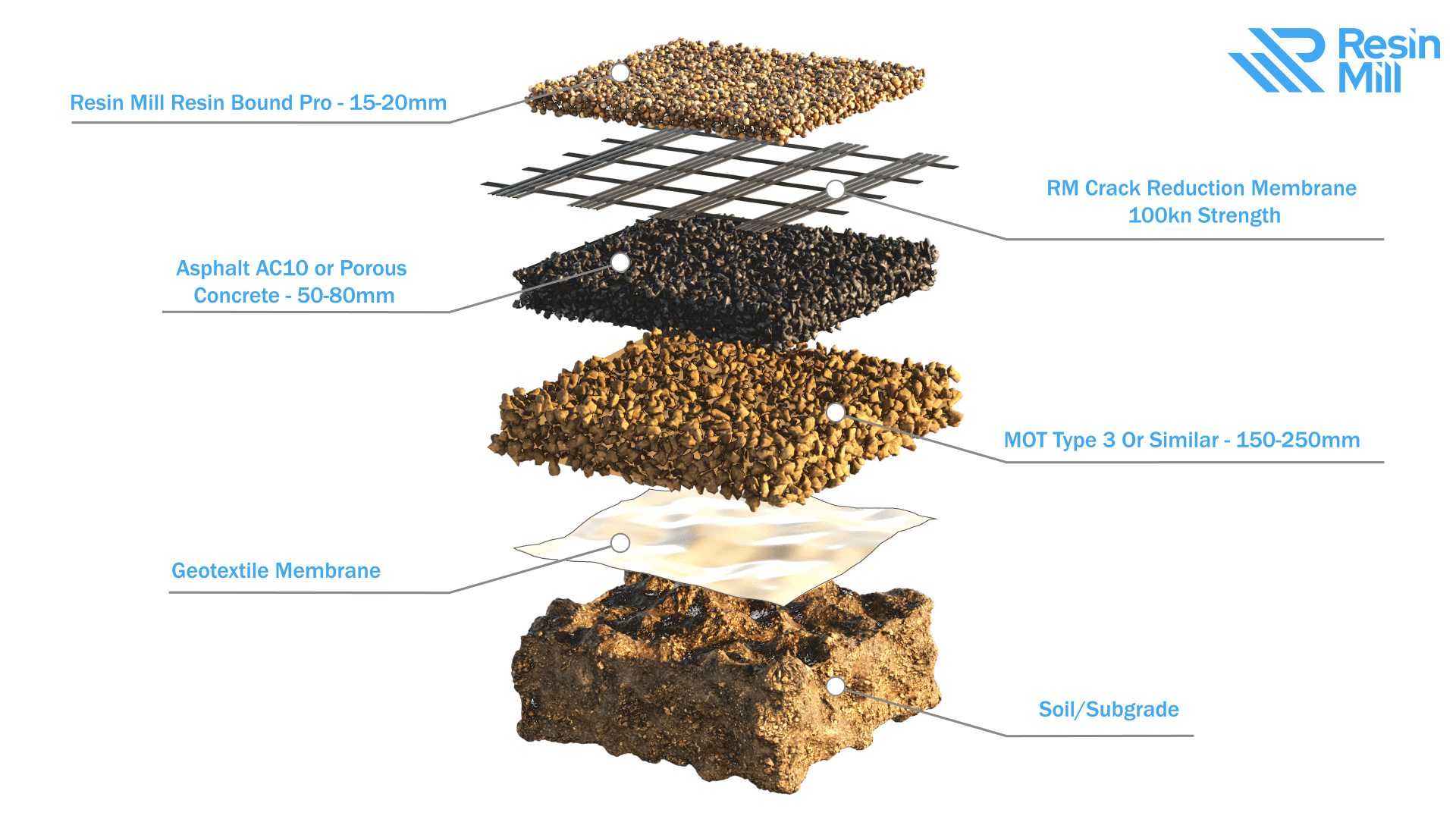

SUB BASES & UNDERNEATH YOUR RESIN BOUND SURFACE

A high-quality resin bound surface starts from the ground up...literally. The foundations and build-up beneath your resin bound installation are crucial for ensuring long-term durability, proper drainage, and a smooth, crack-free finish. Cutting corners at this stage can lead to costly issues down the line. To understand what goes into a professional resin bound job, check out the diagram below for a clear breakdown of each layer.

Breakdown Of Each Layer Within Your Surface

Resin Mill Resin Bound Pro (15–20mm)

- This is the top decorative and functional surface layer, made from natural

aggregates bound together with a high-performance UV-stable polyurethane resin. - It creates a smooth, durable, and aesthetically pleasing finish that is fully

permeable, allowing water to drain through. - Designed for pedestrian and light vehicular traffic, it offers slip resistance, low maintenance, and long-term resilience against weathering.

Resin Mill Crack Reduction Membrane (100kN strength)

- A heavy-duty, high-strength reinforcing membrane that acts as a flexible layer between the base and the resin surface.

- It helps prevent reflective cracking from movement or settlement in the sub-base

or base layers from transferring to the resin surface. - Made from polymer-based geogrid or geotextile material, it enhances the structural integrity of the system.

Asphalt AC10 or Porous Concrete (50–80mm)

- This is the structural base layer that supports the resin-bound surface, typically composed of either asphalt concrete (AC10) or open-textured porous concrete.

- It provides a stable, load-bearing platform while still allowing water to pass

through if porous variants are used. - The choice between AC10 and porous concrete depends on required strength,

permeability, and site conditions.

MOT Type 3 or Similar (150–200mm)

- A sub-base layer made from crushed, graded aggregates with reduced fines content to improve permeability.

- It offers high load-bearing capacity and allows water to filter through to lower

layers, making it ideal for SUDS-compliant systems. - Commonly used in permeable paving setups, this layer supports the layers above while ensuring structural integrity and drainage.

Geotextile Membrane

- A permeable fabric layer placed between the subgrade and the sub-base to prevent soil migration and mixing with the aggregates.

- It acts as a filtration and separation layer, aiding long-term system performance

and stability. - Made from synthetic polymers such as polypropylene or polyester, it is rot-resistant and designed for ground contact.

Soil/Subgrade

- The native ground or prepared earth surface on which all other layers are built.

- Its role is to support the entire paving system; it must be compacted and assessed for bearing capacity and drainage suitability.

- Varies in composition depending on location, but typically includes clay, silt, sand, or combinations thereof.

Lifetime Colour Lock Guarantee

We offer a lifetime colour lock guarantee when installing any of our resin bound colour mixes using Resin Bound UVR Pro products. We can certify that the colour of the resin used will not yellow when using our UV-stable resin.

Still Cant Decide? Order A Sample

Before investing in a full project, you can order free resin bound colour samples so that you can get an idea of what look and style is right for you. This gives you the chance to explore and compare the range of colours available, making sure that you make the best decision for your outdoor space.

Our team is always available should you have any queries or require more information about our products.

Why Resin Mill?

The Resin Mill Delivery Promise

One order. One invoice. One delivery. We offer the latest delivery cut off points in the industry. On time, next day delivery when ordered before 2pm. Our delivery service will not be beaten. Any problems – we sort them.

Unrivalled Advice. Unlimited Support.

With years of hands on experience, there is no question we can’t answer or situation we can’t resolve. As the original one stop shop, for us our job is never finished and our after sales team is always available to help, even out of hours.

Online Ordering. Anytime, Anywhere, Any Place.

Our online portal allows you to order your resin driveway materials whenever and wherever you like, 24 hours a day 7 days a week. Prefer to speak to one of our friendly sales team? No problem, you can still contact us by phone too.