Bases For Resin Driveways

Can I lay resin bound material on to flags?

You cannot lay resin bound permeable paving directly on some surfaces. This includes flags, block paving, MOT type 1 or brick paving. This is due to the fact they are not a solid base. If there is any movement or settlement in the base, the resin bound system will crack.

Cracks caused by base movement in concrete slabs are rare but economic considerations and increased construction thickness often dictate that resin bound surfacing should be applied to asphaltic bases.

So what surfaces can I lay my resin bound aggregates on?

1- Tarmac

Tarmac and concrete are the most suitable bases for resin driveways. The Resin Mill’s permeable resin bound materials can be laid directly onto an existing tarmac surface if it is in suitable condition, or (after sufficient time), a newly installed one. Tarmac must be laid on an appropriate sub base, usually MOT type 3, with adequate depth, in order to support the expected weight of use.

2- Concrete

Existing concrete must be thoroughly cleaned and primed with a polymer primer prior to the installation of the permeable paving. If a primer is not laid, the two surfaces will fail to adhere and your resin drive materials will be wasted, the only way of rectifying the surface, will be to re-start the project with a new batch of resin bound supplies. In addition to the primer gluing the two surfaces together, it also helps prevent de-lamination between the surface and the concrete. The primer also creates a barrier between the two surfaces, which prevents the concrete absorbing the resin out of the stone in the mixture. This is especially important for fresh concrete.

If the concrete has been newly set, (on a sub-base of ideally MOT type 1), there must be a minimum of seven days before the initiation of the resin bound. Sometimes it can take up to a month to cure. Again, the surface must be primed with a polymer based primer before the porous pavement be installed.

3 – Grid systems

Grid systems can also be used to support resin bound aggregates. However double the quantity of resin bound supplies are needed, and so can be costly.

What can I lay my resin bound gravel near?

Resin bound gravel can be installed against house walls, block edging, key curbs, pin curbs, fences, and aluminium beading.

What is resin bound paving?

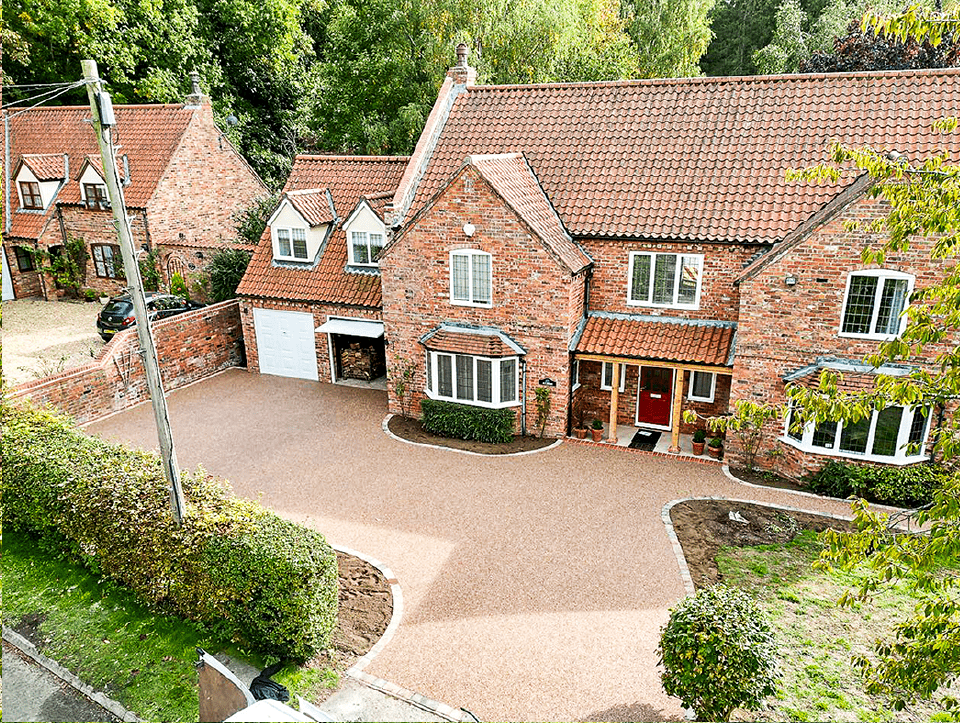

Resin bound paving bonds together tiny stones with high-tech resin to form a solid, visually appealing surface. It forms several small gaps that permit water to drain through into the ground.

Will my resin bound ever crack?

The Resin Mill’s resin bound is a flexible polyurethane system. The only reason it would crack is if there was reflective cracking in the sub base. You can however combat reflective cracking. You can do this by enlarging the crack in the cement and filling it with resin based crack filler. This will halt reflective cracking in the resin paving.

For more information on resin bases please read this article: The best base for resin bound driveways. And for further advice on resin bound surfaces or for resin drive materials, please contact The Resin Mill on 01484 400 855 or email us.

How can I be sure to get the highest standard resin driveway?

The resin overlay is only as good as the base underneath it. As the UK’s only resin bound affiliate partner of HICS, we promote only the best base work and resin bound surfacing installations.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.