When deciding what base to choose for your resin bound gravel installation, it is first important to establish whether there is a suitable existing base that can be utilised.

Resin-bound can be overlaid onto existing tarmac or concrete surfaces of suitable construction for the expected traffic. They need to be crack-free and in good condition. If there is any possibility for movement in the concrete or tarmac, the resin overlay surface can fail.

Generally, when installing an overlay, the current base will not be permeable. In most circumstances, if a new base is to be installed, contractors can ensure it is permeable and SuDS (Sustainable Urban Drainage System) compliant.

Longer guarantees can often be offered when contractors install the full base build-up themselves. This is because you know the base build-up has been installed in line with best practice for resin bound and there are no nasty surprises at a later stage.

What is the base?

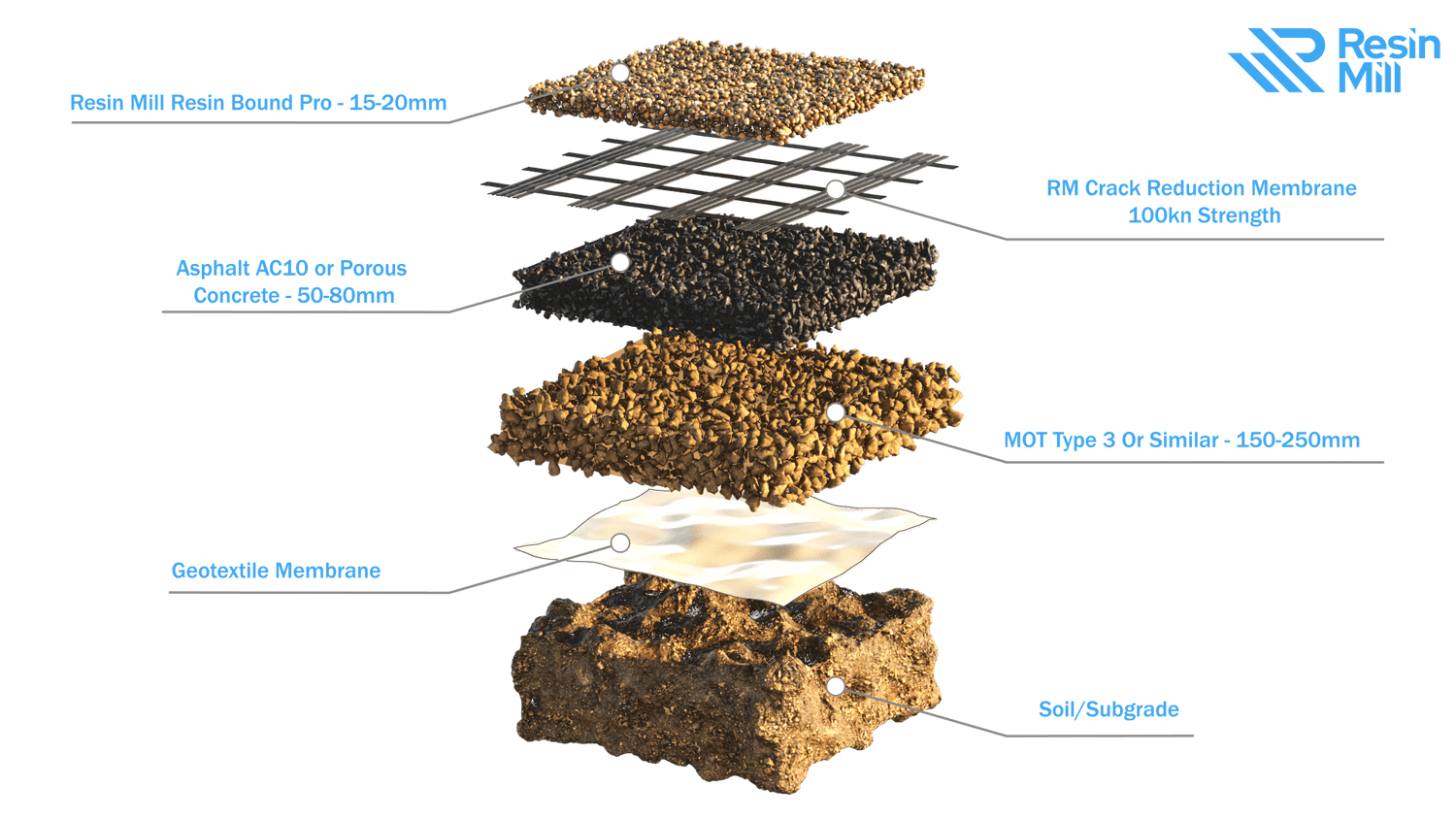

When it comes to resin bound gravel, there is often some confusion with the terminology 'base' and 'sub-base'. However, the 'base' is the binder course and refers to what the resin is immediately laid on.

What is the sub-base?

The 'sub-base' refers to what is underneath the 'base' course. However, some people can also refer to the whole base build-up structure underneath the resin-bound gravel as a 'base', so it is important to be clear which part is being referred to when discussing bases.

What are the functions of the sub-base?

The sub-base has two functions. One is to provide a working platform for the base, and the other is to increase the intrinsic strength of the construction of the resin bound system.

What is the best sub-base for resin bound gravel?

The best sub-base to use for resin bound gravel is a well-compacted bed of non-frost susceptible MOT type 3. The primary reason it is the best for resin bound systems is that it is SuDS compliant.

MOT type 3 has much fewer fines in comparison to other sub-base materials and so as water permeates through the system, it is less likely to move and cause sinkage. The thickness of the sub-base should be calculated subject to survey and dependent on the condition of the soil below. The general guidelines, however, are that it should be laid between 100-250mm.

What are the functions of the base?

The base provides the binding structure for the resin bound gravel. It creates a smooth surface to lay the resin bound gravel on.

What are the different types of bases available for resin bound?

1. Tarmac

There are different types of tarmac available and two different ways to grade tarmac: the hardness and the size of the stone.

There are different types of tarmac available and two different ways to grade tarmac: the hardness and the size of the stone.

A 'pen' rating is what calculates the hardness of the bitumen. The lower the number of the 'pen' rating, the harder the bitumen is and the more brittle it is. If it is too brittle, it will crack. The higher the number of the 'pen', the softer the bitumen is.

The size of the stone is measured in 'mm' and is represented after the 'AC' (asphalt content). When installing tarmac as a base for resin drives, it is all about getting the right balance so that it can withstand hot and cold temperatures without cracking.

How thick is tarmac on a resin bound driveway?

You should generally be laying 70mm worth of tarmac as a base coat when laying resin bound.

What is the best tarmac spec when laying resin bound gravel?

AC14 open textured 14mm tarmac is the best base for resin driveways. This AC14 tarmac permeable tarmac makes the system SuDS compliant by allowing rainfall to permeate slowly through to a soakaway. 14mm is the preferred size of stone in asphalt because it is more tightly knitted and there are more contact points, creating a stronger bond.

For standard resin driveways, the pen rating of the tarmac should be 100-150. This should not soften until the temperature gets to 40°c. However, warmer temperatures soften the tarmac. So, if you are based in the south of England, in places such as Essex or Kent, AC14 open textured should be laid but with a 40-60 pen rating as this will not soften until temperatures reach 50°c.

A limestone-based tarmac is the best option for resin driveways because it has less thermal expansion. This means that as it starts to get warm and the tarmac begins to expand, the resin is less likely to crack. Limestone-based tarmac is more readily available in central England. The north and the south of England have different granites with a greater rate of expansion, so it is always best to check with your asphalt supplier.

How long do I need to leave tarmac to dry before laying resin bound gravel?

As a rule of thumb in average weather conditions, tarmac needs to be left to set for a minimum of 2 weeks in order to let the oils deplete. We do however, always recommend that you speak to the tarmac plant before laying your base for resin bound.

Pros

- Permeable and complies with SuDS

- It's a strong base

- Quicker curing time than concrete

- Very cost-effective for average to large jobs

Cons

- More skill is required to lay it compared to concrete

- It can be expensive when requiring very small amounts

- Susceptible to price fluctuations

2. Concrete

Concrete is graded in newtons. The Newton grade number of the concrete is placed after the 'C' when looking at specifications, for example, 'C20'. The higher the Newton grading, the stronger the concrete. Concrete, as it is, is not permeable and so does not allow water to flow through it.

Concrete is graded in newtons. The Newton grade number of the concrete is placed after the 'C' when looking at specifications, for example, 'C20'. The higher the Newton grading, the stronger the concrete. Concrete, as it is, is not permeable and so does not allow water to flow through it.

To adhere to SuDS compliance and for a resin bound system to be permeable, special permeable concrete must be used. An aco drain can be laid when installing concrete on a slope to collect the water draining through the resin bound. Some contractors drill holes in the concrete or place vertical piping going through it to the sub-base to allow for water flow. Whilst this helps with drainage, it is not SuDS compliant.

How much concrete should I be laying?

You should generally be laying 100mm worth of concrete as a base coat when installing resin bound gravel.

What is the best concrete spec when laying resin bound gravel?

The best concrete to use is C20 concrete.

How long do I need to leave the concrete to dry before laying resin bound gravel?

Concrete dries out at different rates depending on the humidity. The general rule of thumb is that you should leave the tarmac sub-base for at least 4 weeks. This will help it develop to its maximum strength as well. Concrete should be smooth-brushed before curing. A primer must be laid in order to create better adhesion of the resin bound aggregates.

Pros

- Concrete is generally cheap and easy to lay

- Easy to source

- Self-levelling almost

- Strong base

Cons

- Not naturally permeable

- Longer curing time is needed before laying resin bound aggregates

- Have to mirror any joints in the concrete in the resin bound surface course

- Primer is required on all concrete installations, new or existing

3. EcoGrid

EcoGrid is a grid made of recycled plastic materials, and it comes in different specifications. It creates a locked, grid-like structure to bear heavy loads and is laid on top of a geotextile membrane, which is laid on top of the bed of type 3 sub base. It needs to then be filled with clean stone before laying the resin bound aggregates. Regarding the stone it needs to be filled with, the smaller the better.

EcoGrid is a grid made of recycled plastic materials, and it comes in different specifications. It creates a locked, grid-like structure to bear heavy loads and is laid on top of a geotextile membrane, which is laid on top of the bed of type 3 sub base. It needs to then be filled with clean stone before laying the resin bound aggregates. Regarding the stone it needs to be filled with, the smaller the better.

How much EcoGrid should I be laying?

EcoGrids are 330mmx330mm and arrive on-site in grids of 12, so the amount you will lay will depend on the size of your resin bound installation.

What is the best EcoGrid spec when laying resin bound gravel?

The most common one for carrying the load required for resin bound installations is the E50.

Pros

- Cost-effective for small jobs

- It is highly permeable

- Easy to install

Cons

- It's not as strong as concrete or tarmac

- Requires additional products to be purchased to lay it

What is the best base for resin bound gravel?

The base you choose for your resin bound installation will depend on the project specification. If clients are not fussed about their surface being SuDS compliant, concrete can act as a suitable base.

In order to achieve a SuDS-compliant surface, however, the best base to use is AC14 open textured tarmac at 70mm. This is because open textured tarmac offers a strong, permeable and SuDS compliant base that is cost-effective, with a relatively quick curing time.

The size of the installation will also impact the choice of base. For example, EcoGrid may be more economical for smaller installations where you don't have the economies of scale of installing tarmac. But whilst it is more permeable, it is not as strong as tarmac or concrete.

Surfaces that will be heavily trafficked should have all of the layers designed according to DoT requirements. It is important to note that the advice given is based on best practice for resin bound surfacing and that the project specifier can design different base layers depending on the ground conditions and the expected use of the surface. To help contractors even further, we have created a handy step-by-step installation guide.

Leading the way in quality polyurethane resin

The Resin Mill is the UK's largest supplier, offering trade supplies of resin bound and bonded surfacing materials to contractors across the UK. Give us a call on 01484 400 855 and see how we can help you reduce your costs on resin and dried aggregates by speaking with one of our resin bound advisors today. For more information on base mineral products, click here.

Related to this post: Do driveways have to be permeable?

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.